Description

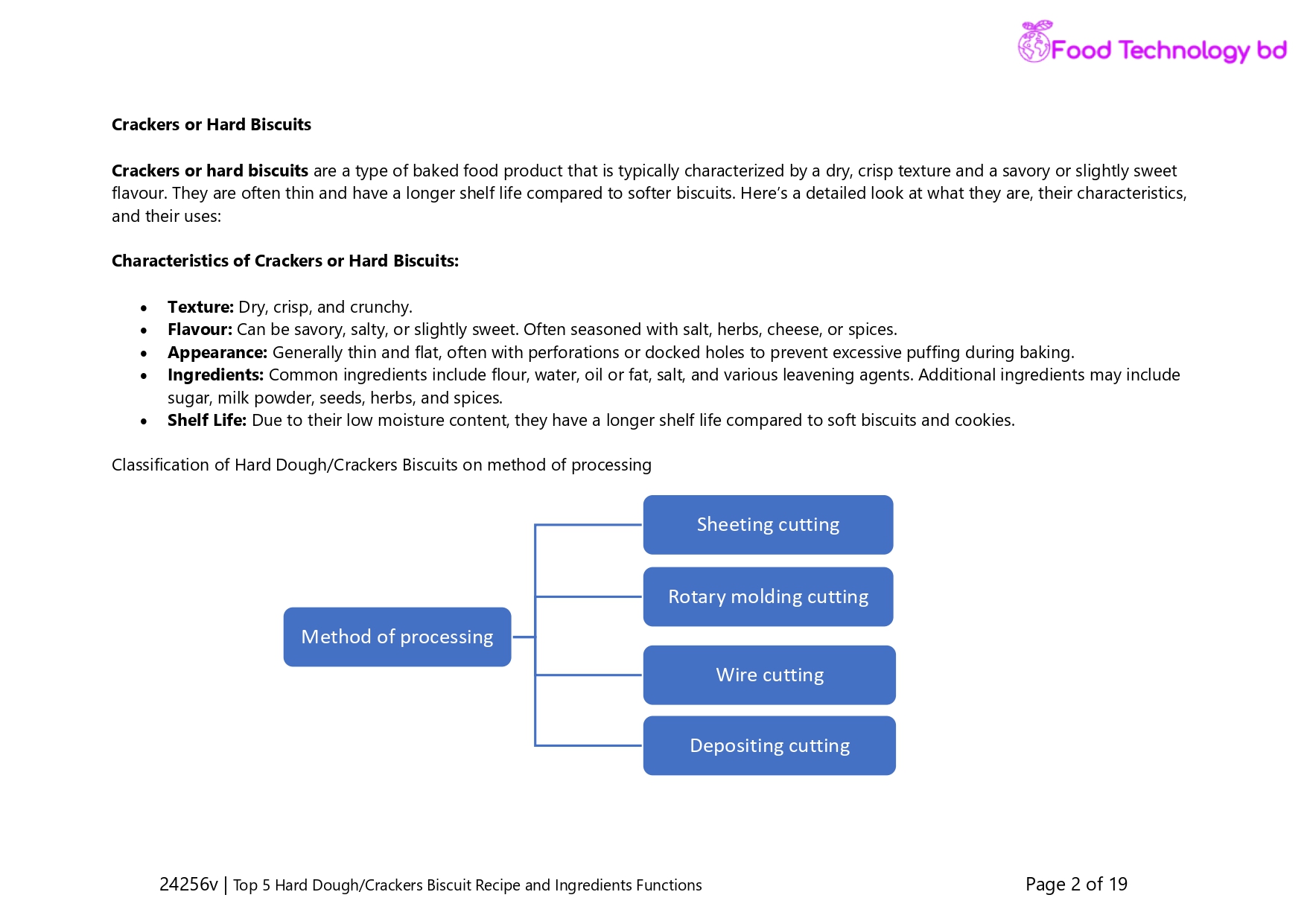

Crackers or Hard Biscuits

Crackers or hard biscuits are a type of baked food product that is typically characterized by a dry, crisp texture and a savory or slightly sweet flavour. They are often thin and have a longer shelf life compared to softer biscuits. Here’s a detailed look at what they are, their characteristics, and their uses:

Characteristics of Crackers or Hard Biscuits:

- Texture: Dry, crisp, and crunchy.

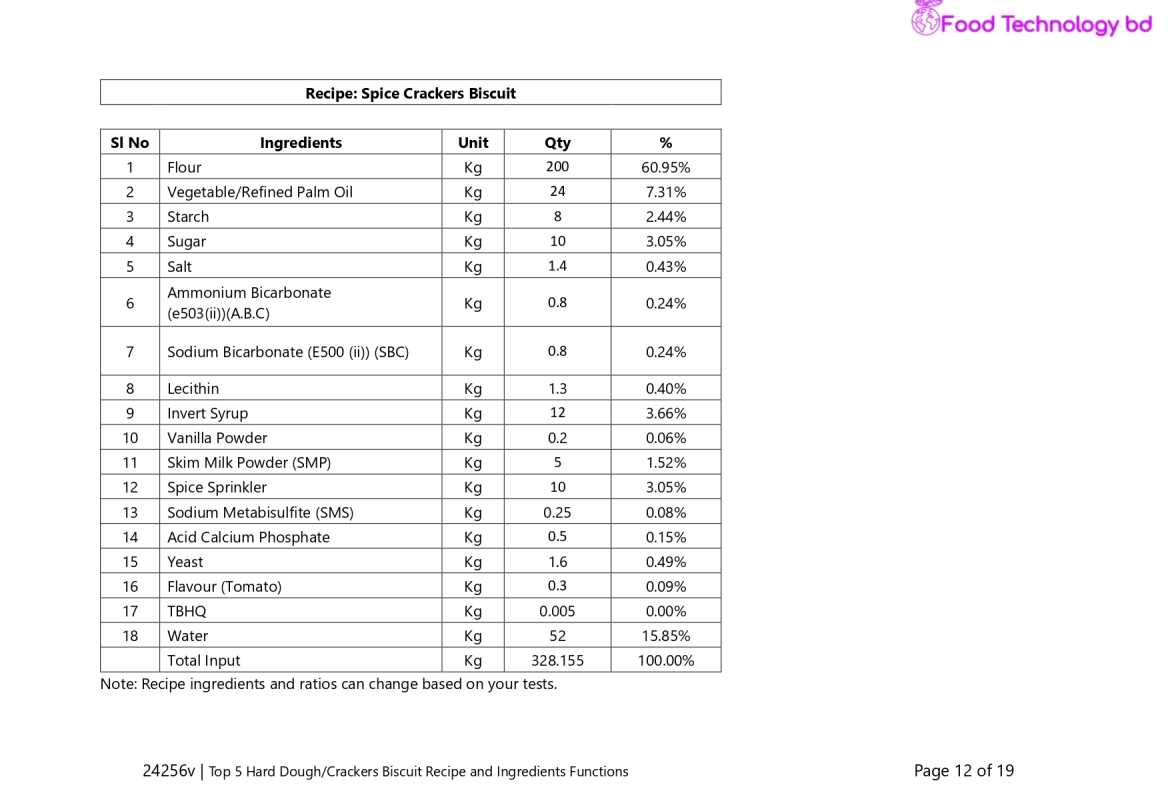

- Flavour: Can be savory, salty, or slightly sweet. Often seasoned with salt, herbs, cheese, or spices.

- Appearance: Generally thin and flat, often with perforations or docked holes to prevent excessive puffing during baking.

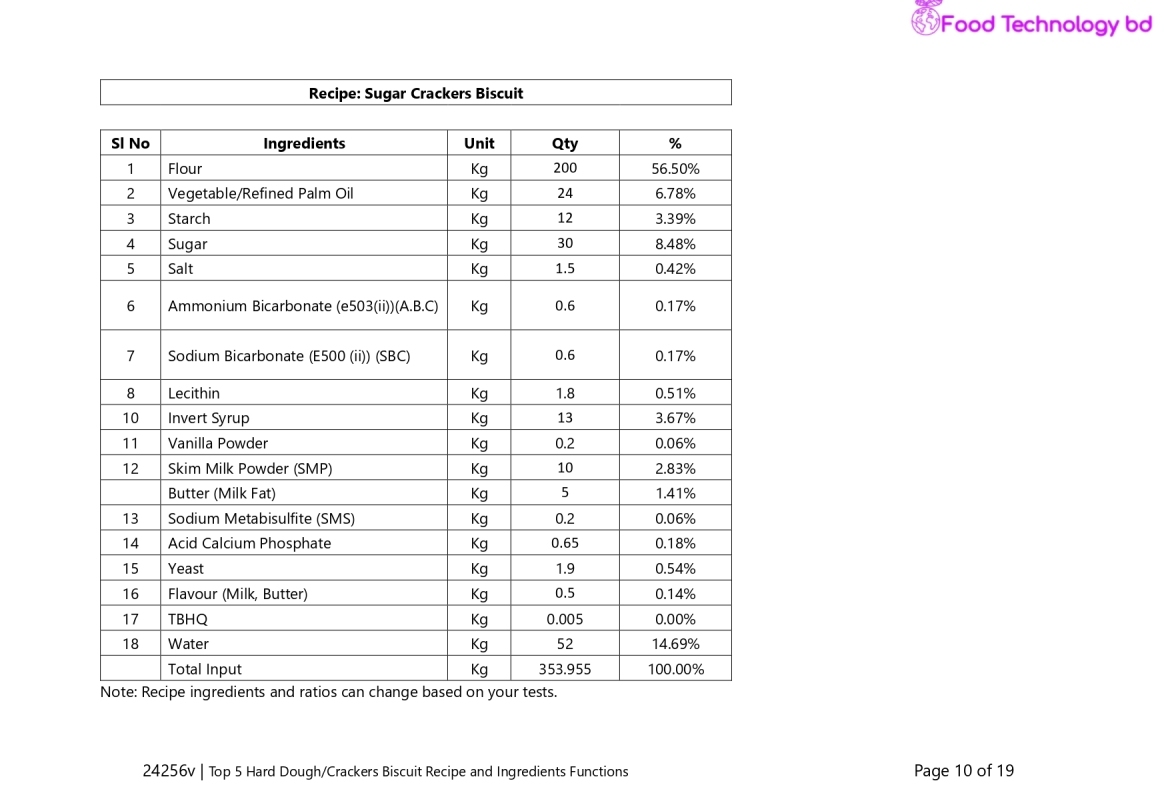

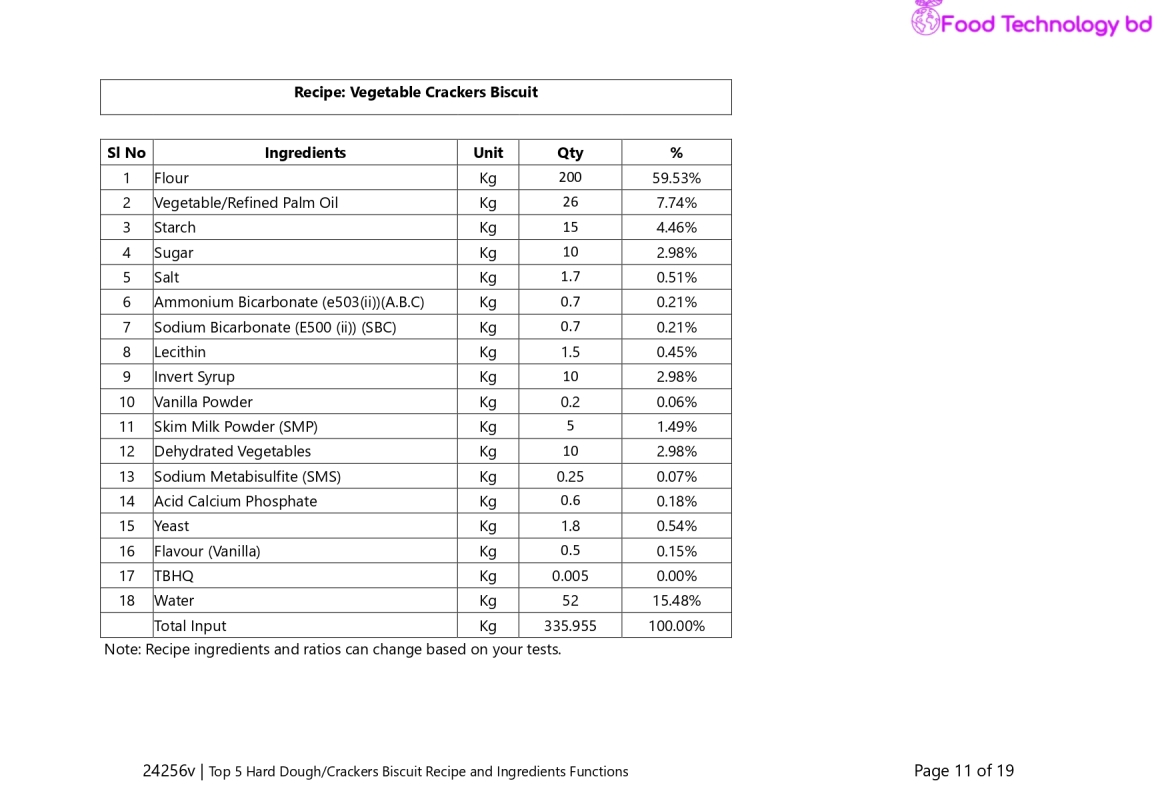

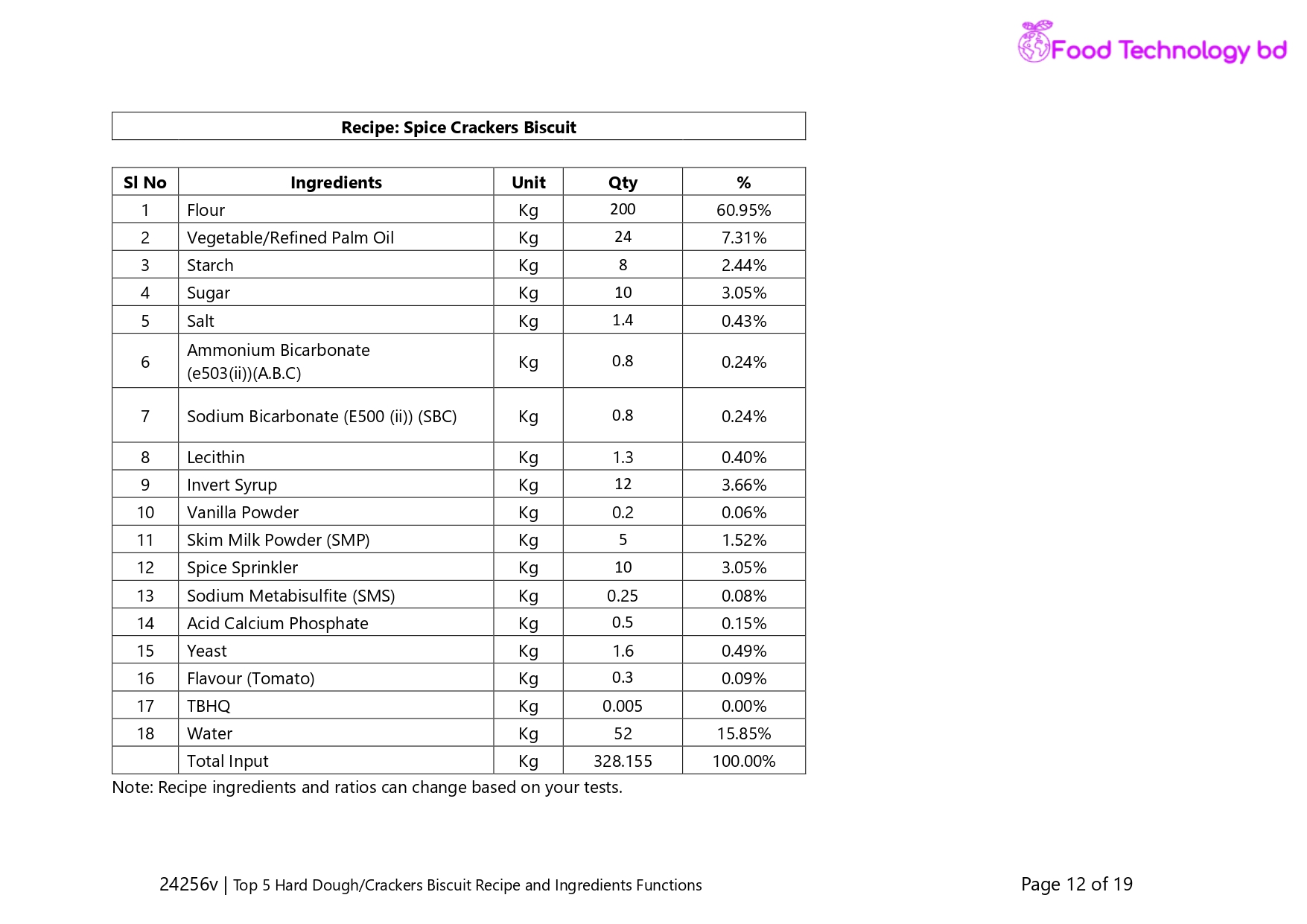

- Ingredients: Common ingredients include flour, water, oil or fat, salt, and various leavening agents. Additional ingredients may include sugar, milk powder, seeds, herbs, and spices.

- Shelf Life: Due to their low moisture content, they have a longer shelf life compared to soft biscuits and cookies.

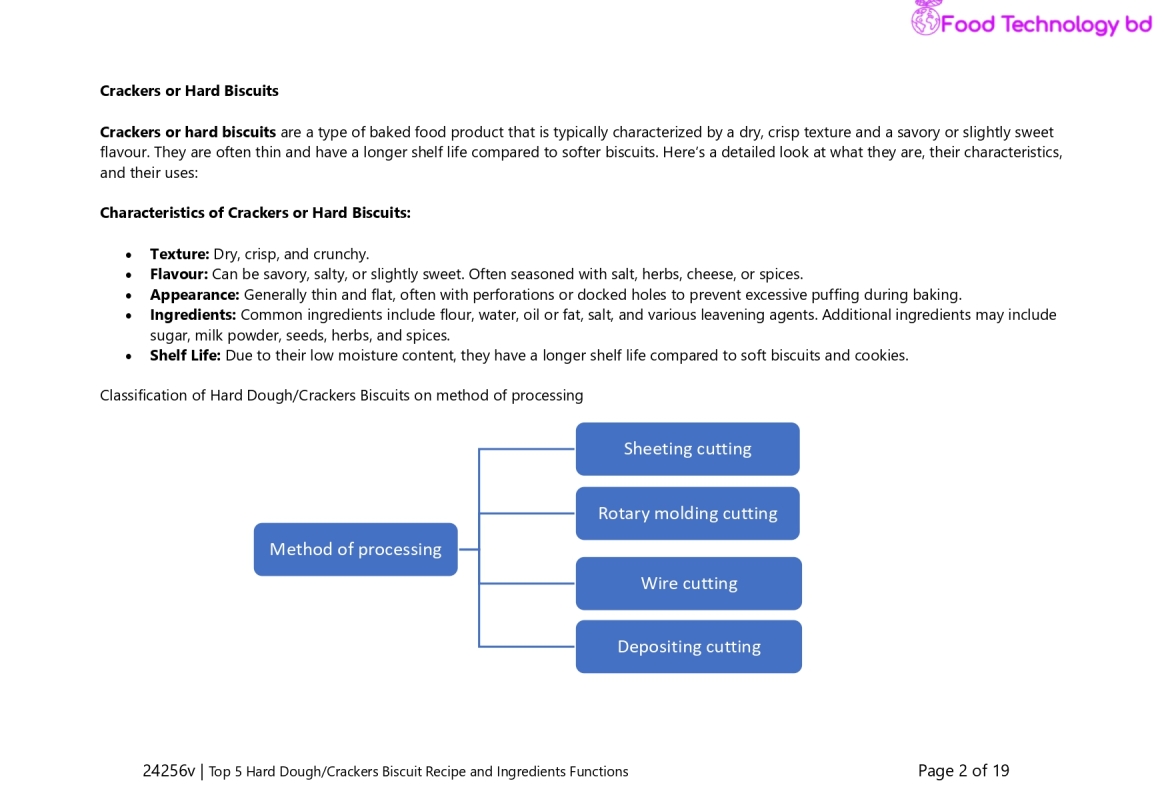

Classification of Hard Dough/Crackers Biscuits on method of processing

Method of processing

- Sheeting cutting

- Rotary molding cutting

- Wire cutting

- Depositing cutting

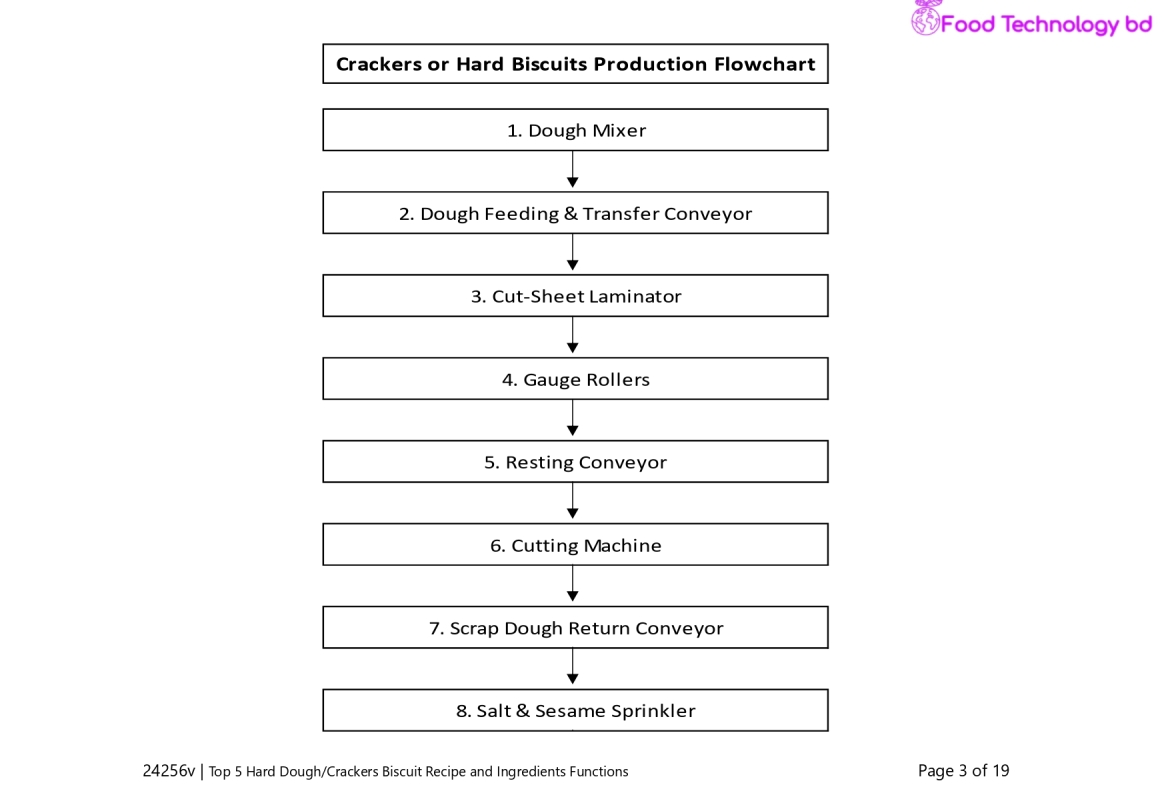

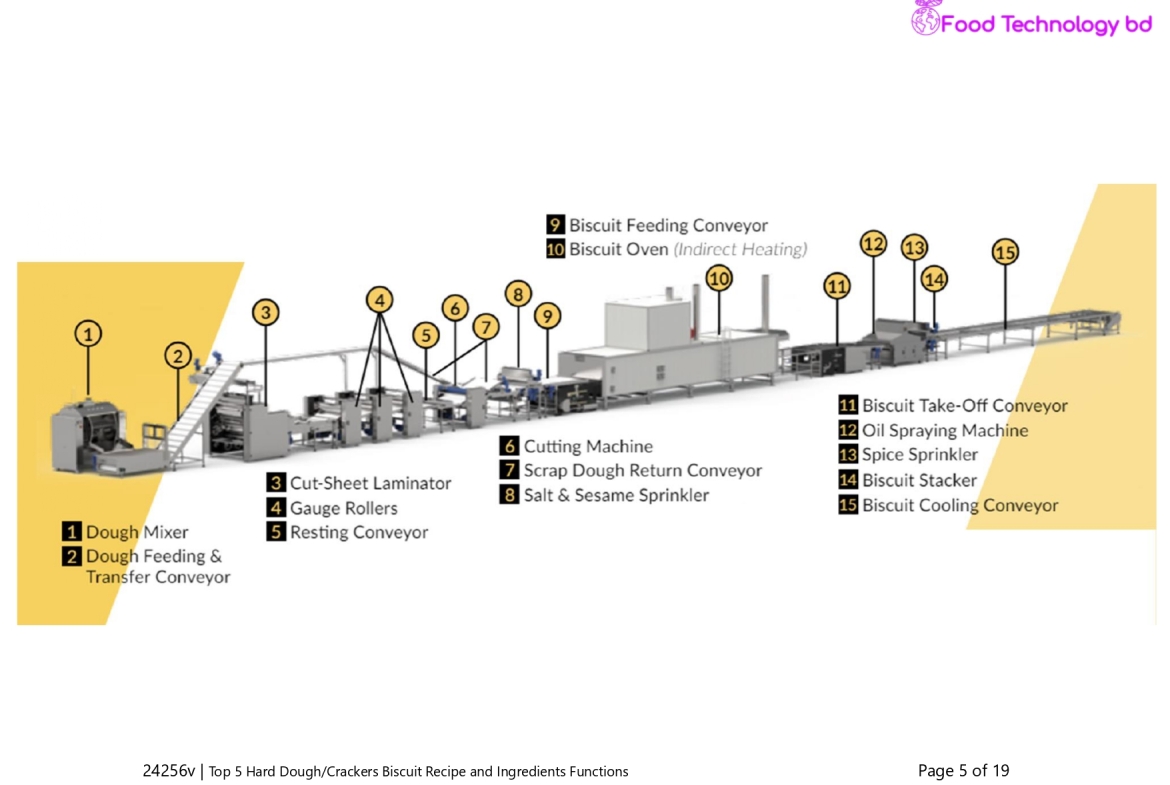

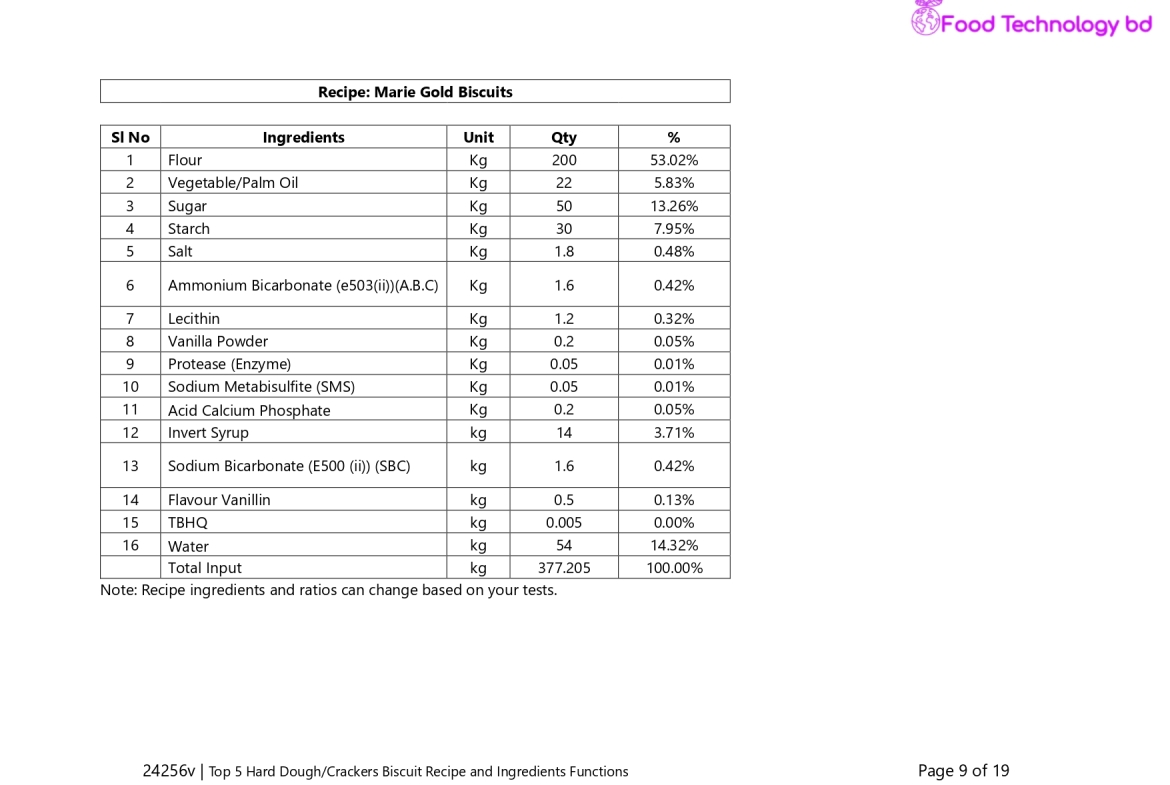

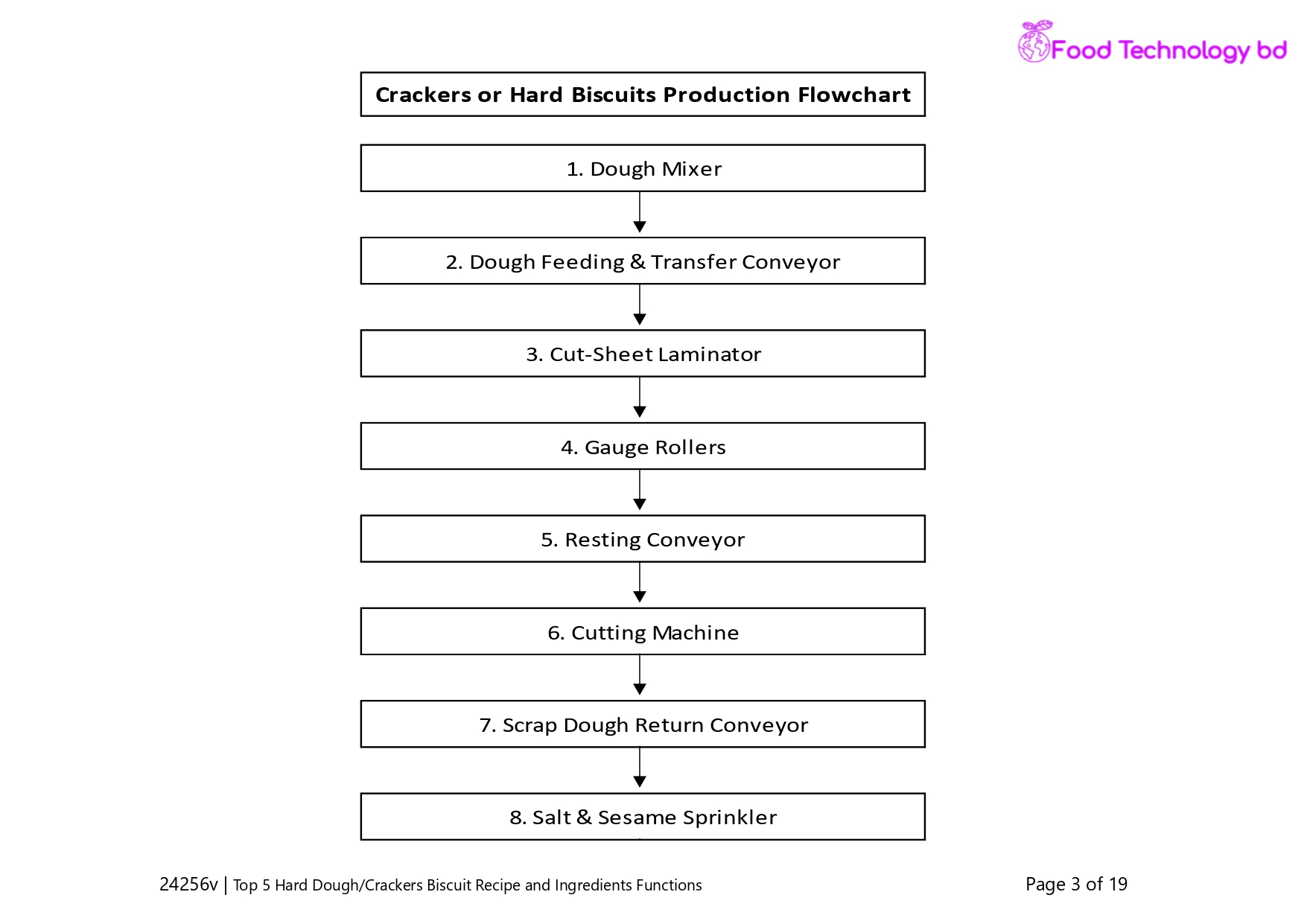

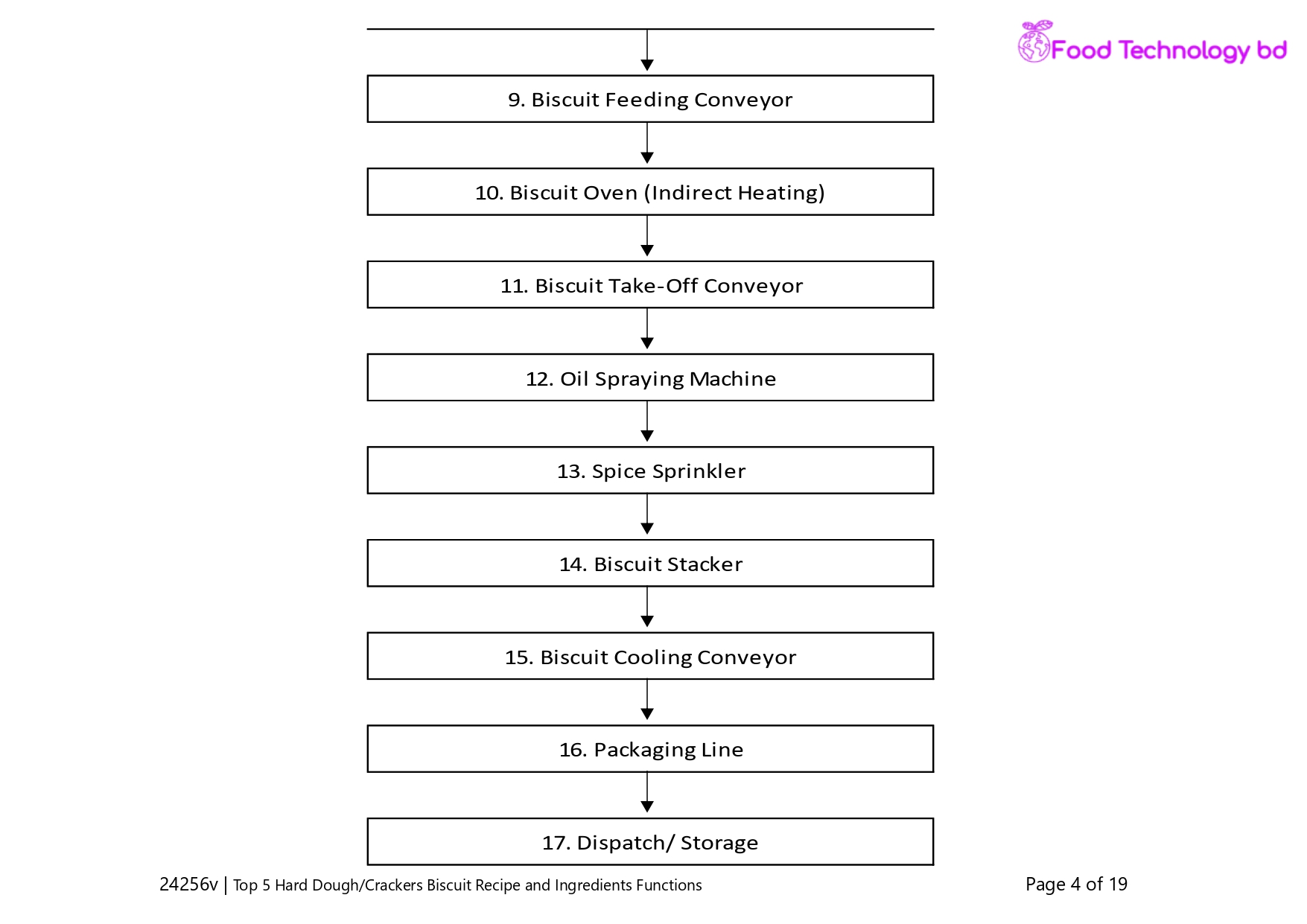

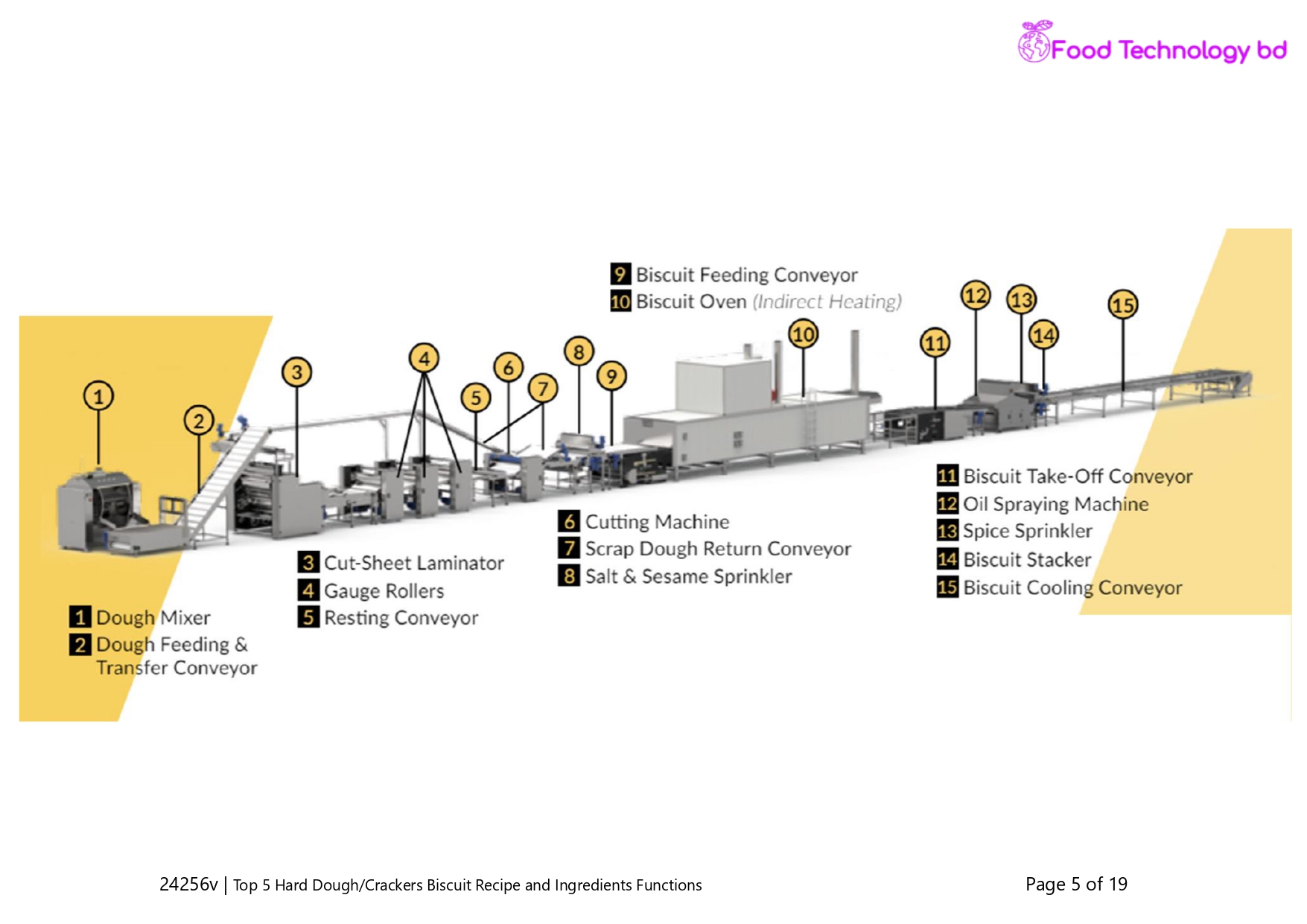

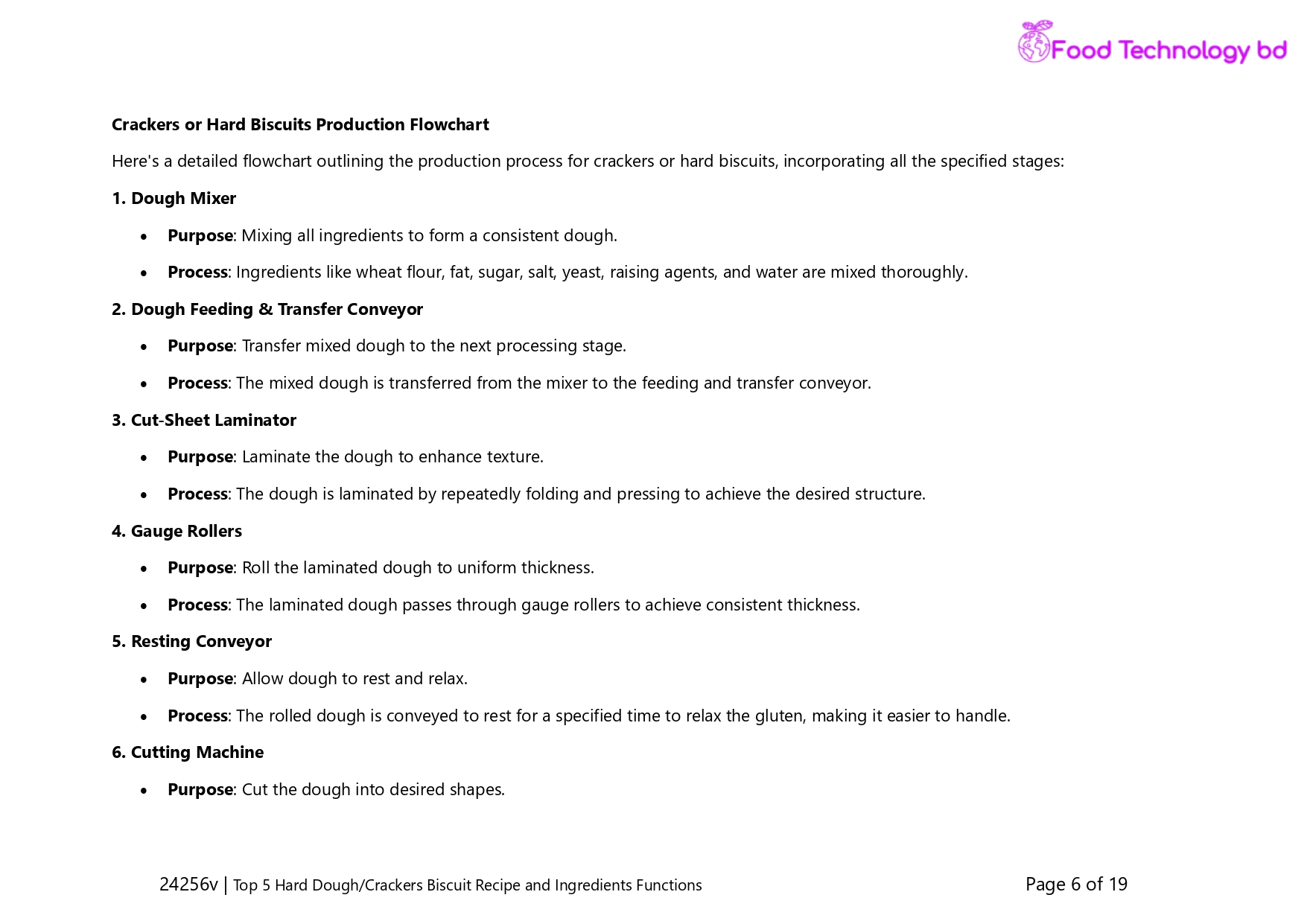

Crackers or Hard Biscuits Production Flowchart

Here’s a detailed flowchart outlining the production process for crackers or hard biscuits, incorporating all the specified stages:

- Dough Mixer

- Purpose: Mixing all ingredients to form a consistent dough.

- Process: Ingredients like wheat flour, fat, sugar, salt, yeast, raising agents, and water are mixed thoroughly.

- Dough Feeding & Transfer Conveyor

- Purpose: Transfer mixed dough to the next processing stage.

- Process: The mixed dough is transferred from the mixer to the feeding and transfer conveyor.

- Cut-Sheet Laminator

- Purpose: Laminate the dough to enhance texture.

- Process: The dough is laminated by repeatedly folding and pressing to achieve the desired structure.

- Gauge Rollers

- Purpose: Roll the laminated dough to uniform thickness.

- Process: The laminated dough passes through gauge rollers to achieve consistent thickness.

- Resting Conveyor

- Purpose: Allow dough to rest and relax.

- Process: The rolled dough is conveyed to rest for a specified time to relax the gluten, making it easier to handle.

- Cutting Machine

- Purpose: Cut the dough into desired shapes.

- Process: The rested dough is cut into shapes using a cutting machine, often with a rotary cutter.

- Scrap Dough Return Conveyor

- Purpose: Recycle scrap dough.

- Process: Scraps from the cutting process are collected and returned to the dough mixer for reuse.

- Salt & Sesame Sprinkler

- Purpose: Add toppings to the cut dough.

- Process: Salt, sesame seeds, or other toppings are sprinkled onto the cut dough pieces.

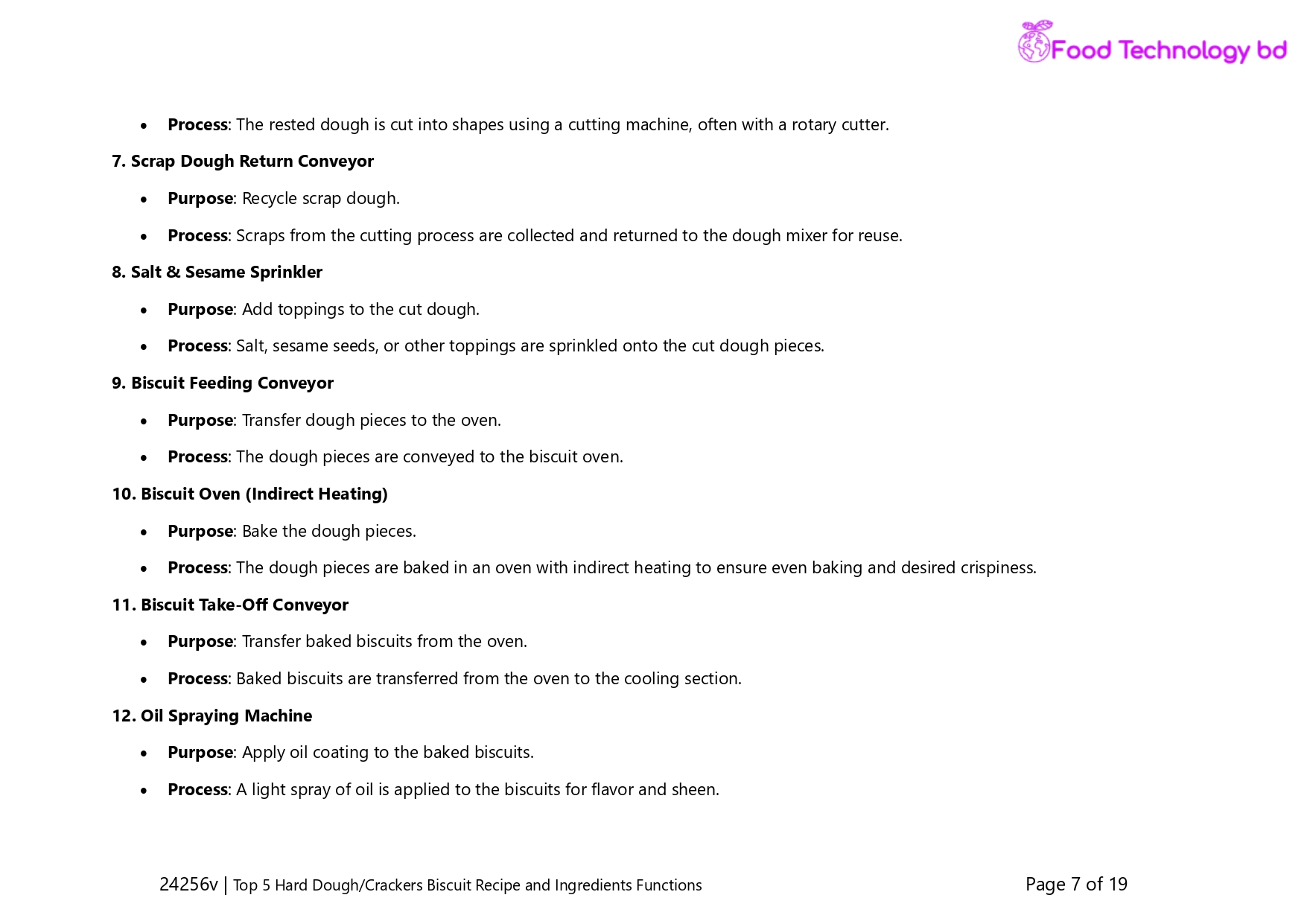

- Biscuit Feeding Conveyor

- Purpose: Transfer dough pieces to the oven.

- Process: The dough pieces are conveyed to the biscuit oven.

- Biscuit Oven (Indirect Heating)

- Purpose: Bake the dough pieces.

- Process: The dough pieces are baked in an oven with indirect heating to ensure even baking and desired crispiness.

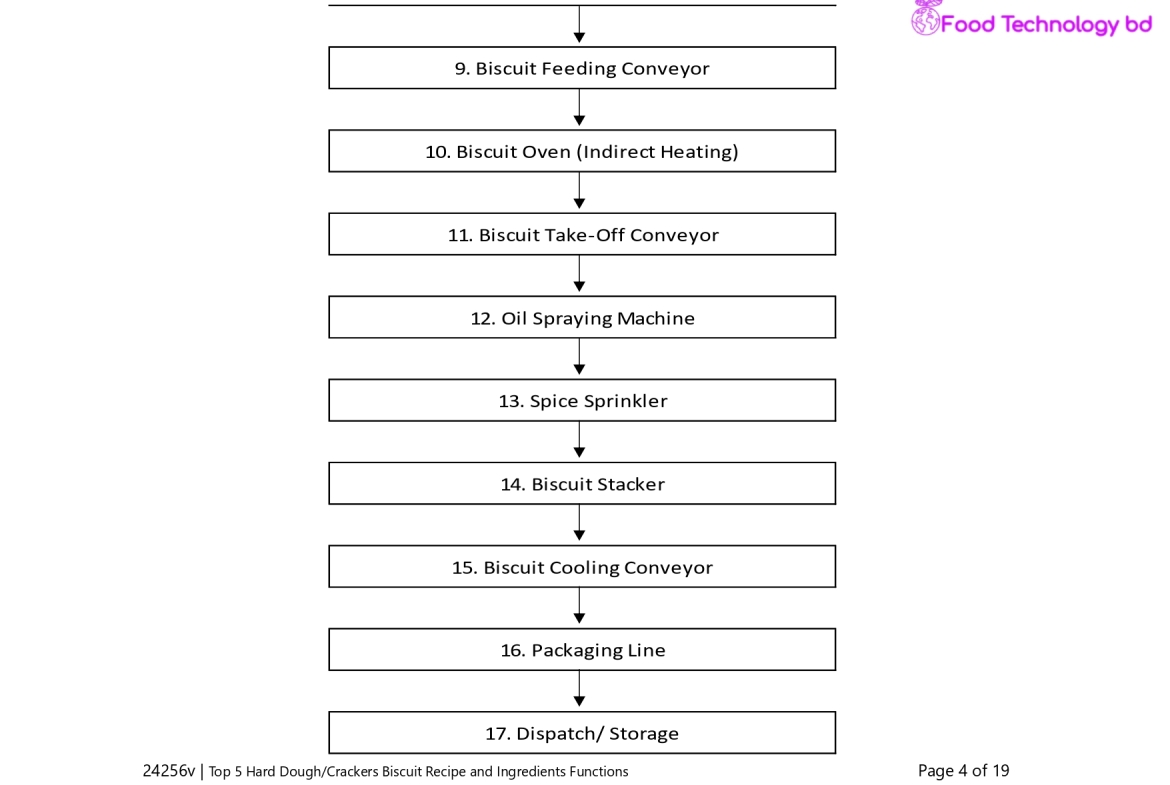

- Biscuit Take-Off Conveyor

- Purpose: Transfer baked biscuits from the oven.

- Process: Baked biscuits are transferred from the oven to the cooling section.

- Oil Spraying Machine

- Purpose: Apply oil coating to the baked biscuits.

- Process: A light spray of oil is applied to the biscuits for flavor and sheen.

- Spice Sprinkler

- Purpose: Add spices to the baked biscuits.

- Process: Spices or flavorings are sprinkled onto the biscuits post-baking.

- Biscuit Stacker

- Purpose: Stack biscuits for cooling.

- Process: Baked and flavored biscuits are stacked neatly for efficient cooling.

- Biscuit Cooling Conveyor

- Purpose: Cool the baked biscuits.

- Process: Stacked biscuits are conveyed through a cooling system to bring them to room temperature.

- Packaging Line

- Purpose: Package the cooled biscuits.

- Process: Cooled biscuits are packed into appropriate packaging for storage and transport.

- Dispatch/Storage

- Purpose: Store or dispatch the packed biscuits.

- Process: Packaged biscuits are stored in a warehouse or dispatched for distribution.

Please see more details in PDF (Download Free)