Free

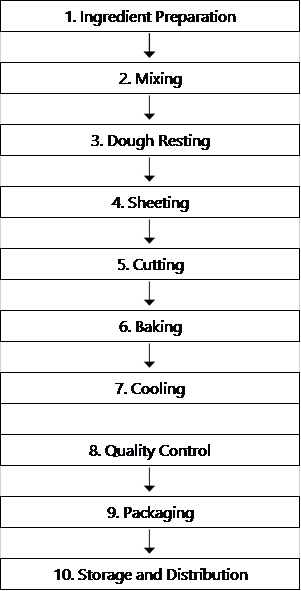

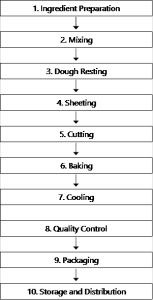

Biscuits Production Flowchart & Machineries

Description

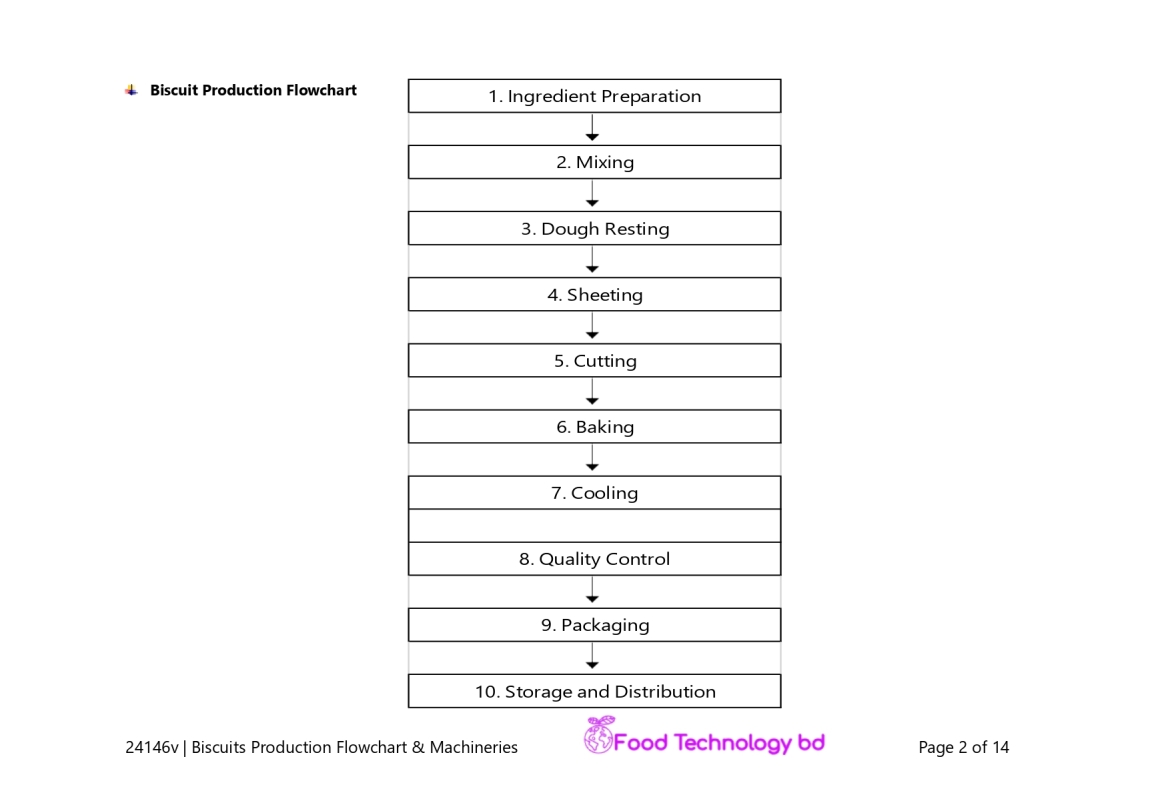

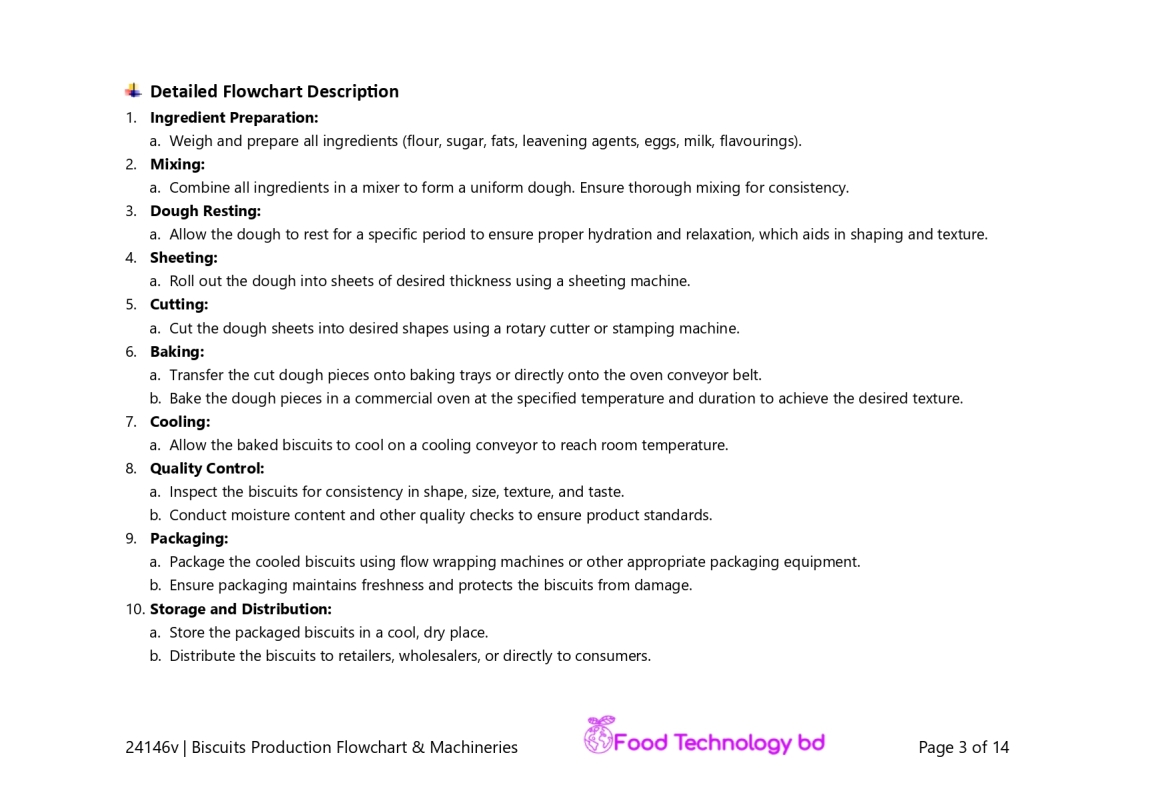

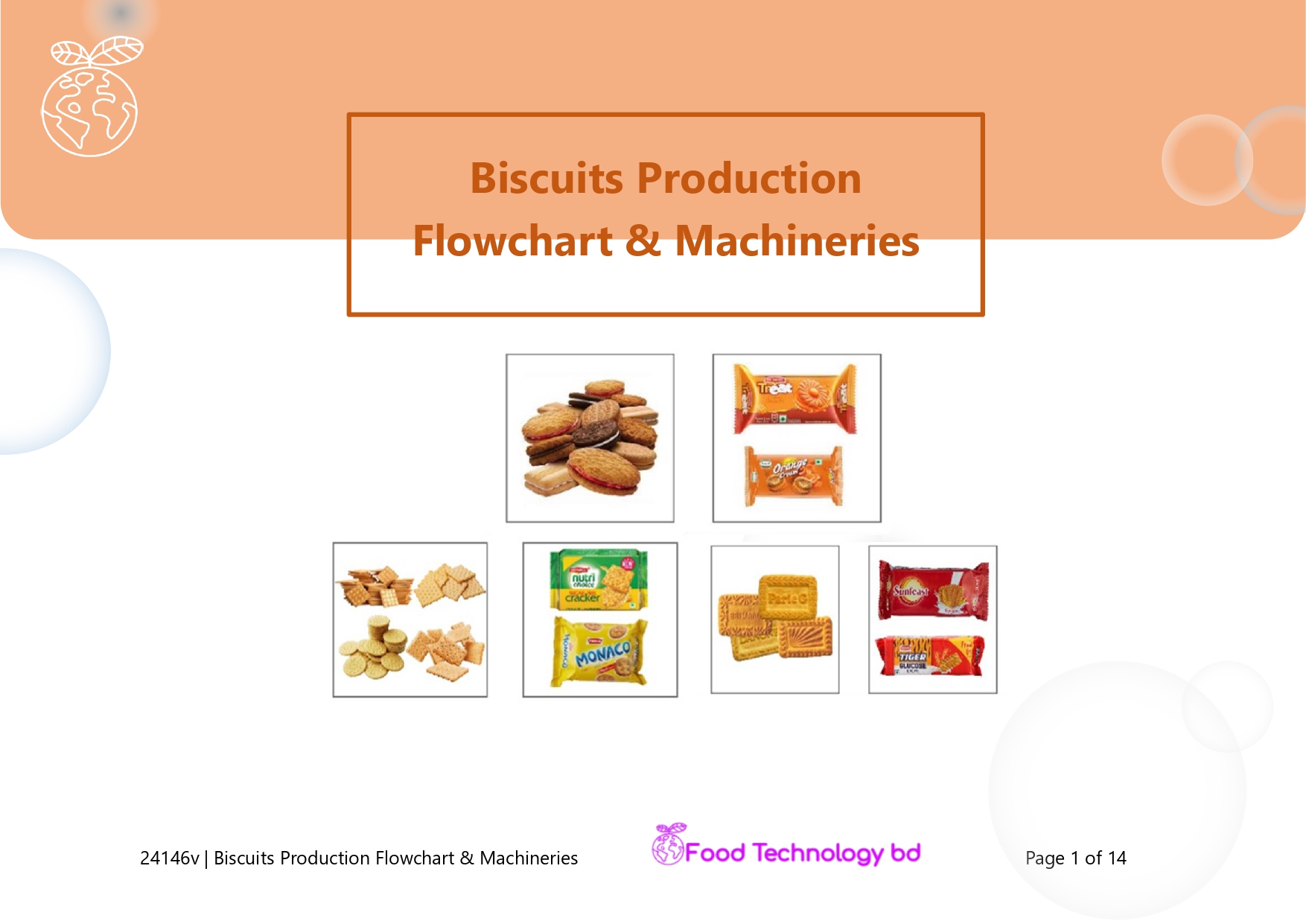

- Ingredient Preparation :

- Weigh and prepare all ingredients ( flour, sugar, fats, leavening agents, eggs, milk, flavorings ).

- Mixing:

- Combine all ingredients in a mixer to form a uniform dough. Ensure thorough mixing for consistency.

- Dough Resting:

- Allow the dough to rest for a specific period to ensure proper hydration and relaxation, which aids in shaping and texture.

- Sheeting:

- Roll out the dough into sheets of desired thickness using a sheeting machine.

- Cutting:

- Cut the dough sheets into desired shapes using a rotary cutter or stamping machine.

- Baking:

- Transfer the cut dough pieces onto baking trays or directly onto the oven conveyor belt.

- Bake the dough pieces in a commercial oven at the specified temperature and duration to achieve the desired texture.

- Cooling:

- Allow the baked biscuits to cool on a cooling conveyor to reach room temperature.

- Quality Control:

- Inspect the biscuits for consistency in shape, size, texture, and taste.

- Conduct moisture content and other quality checks to ensure product standards.

- Packaging:

- Package the cooled biscuits using flow wrapping machines or other appropriate packaging equipment.

- Ensure packaging maintains freshness and protects the biscuits from damage.

- Storage and Distribution:

- Store the packaged biscuits in a cool, dry place.

- Distribute the biscuits to retailers, wholesalers, or directly to consumers.

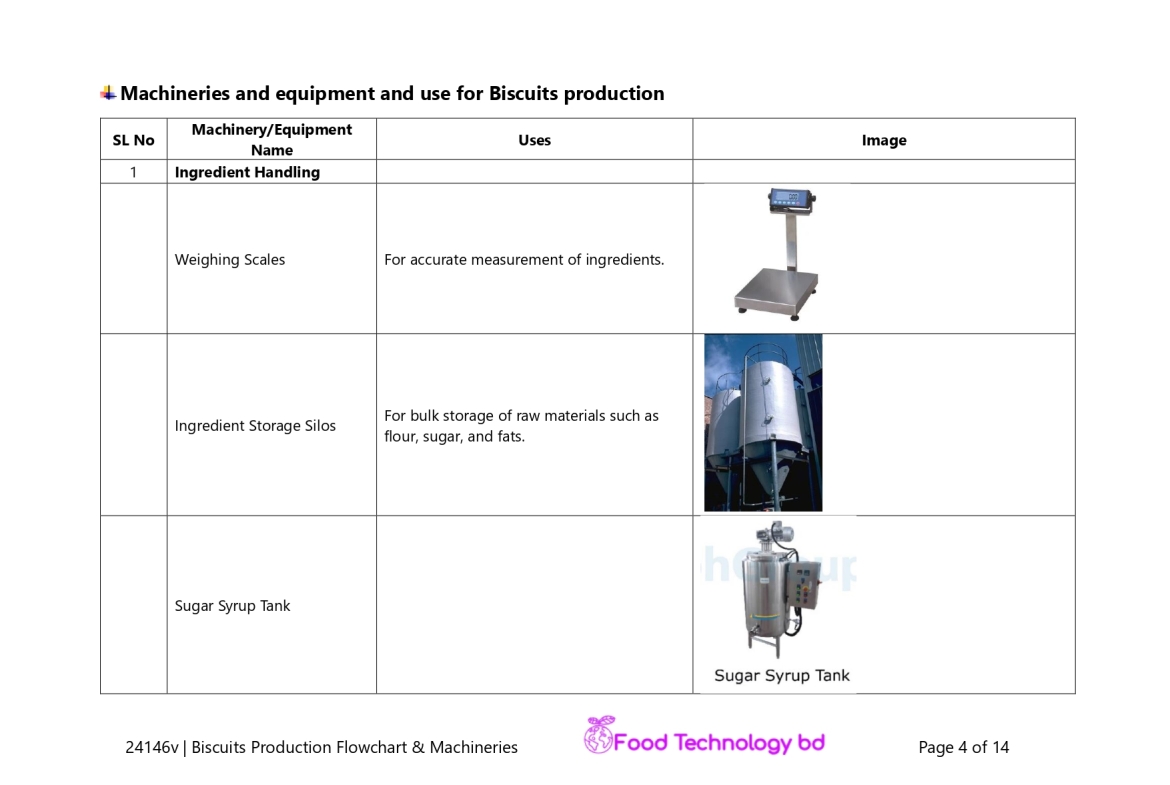

- Machineries and equipment and use for Biscuits production

| SL No | Machinery/Equipment Name | Uses |

| 1 | Ingredient Handling | |

| Weighing Scales | For accurate measurement of ingredients. | |

| Ingredient Storage Silos | For bulk storage of raw materials such as flour, sugar, and fats. | |

| Sugar Syrup Tank | ||

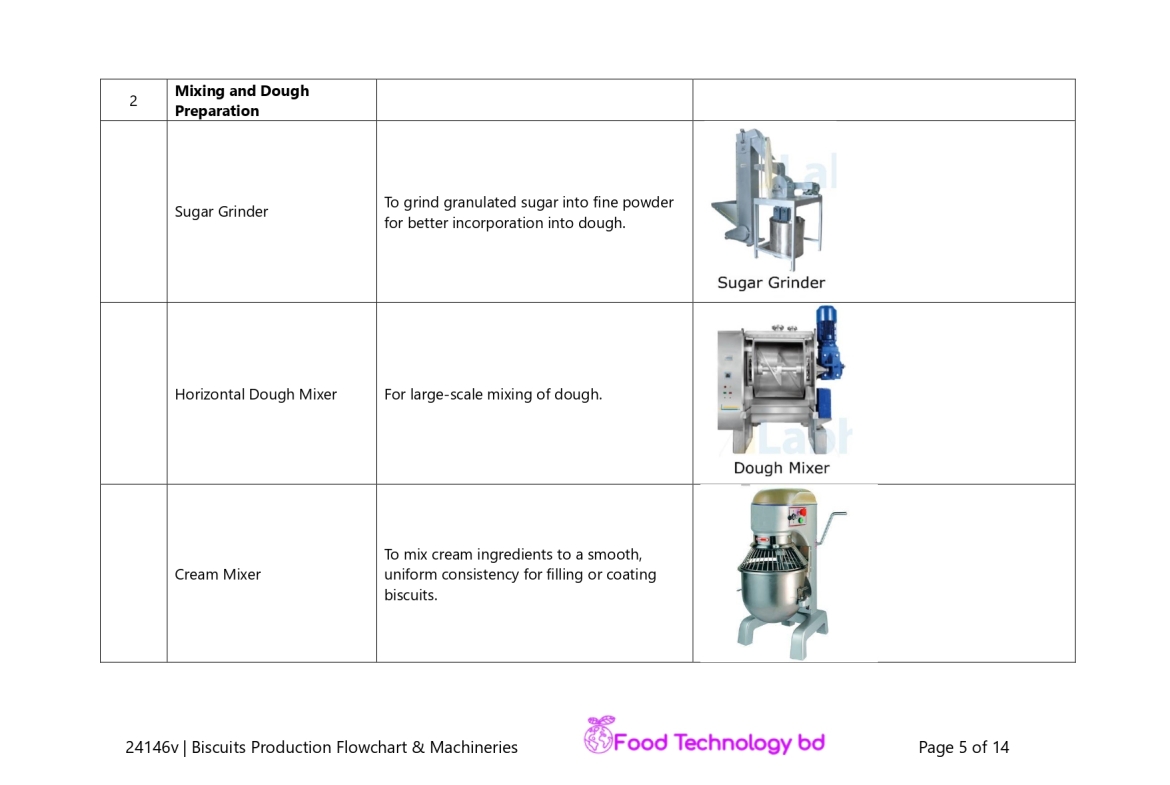

| 2 | Mixing and Dough Preparation | |

| Sugar Grinder | To grind granulated sugar into fine powder for better incorporation into dough. | |

| Horizontal Dough Mixer | For large-scale mixing of dough. | |

| Cream Mixer | To mix cream ingredients to a smooth, uniform consistency for filling or coating biscuits. | |

| 3 | Dough Handling | |

| Dough Feeder | To transfer mixed dough from the mixer to the sheeting equipment. | |

| Industrial SS Tub | To transfer and holding dough from the mixer to the feeder or hopper. | |

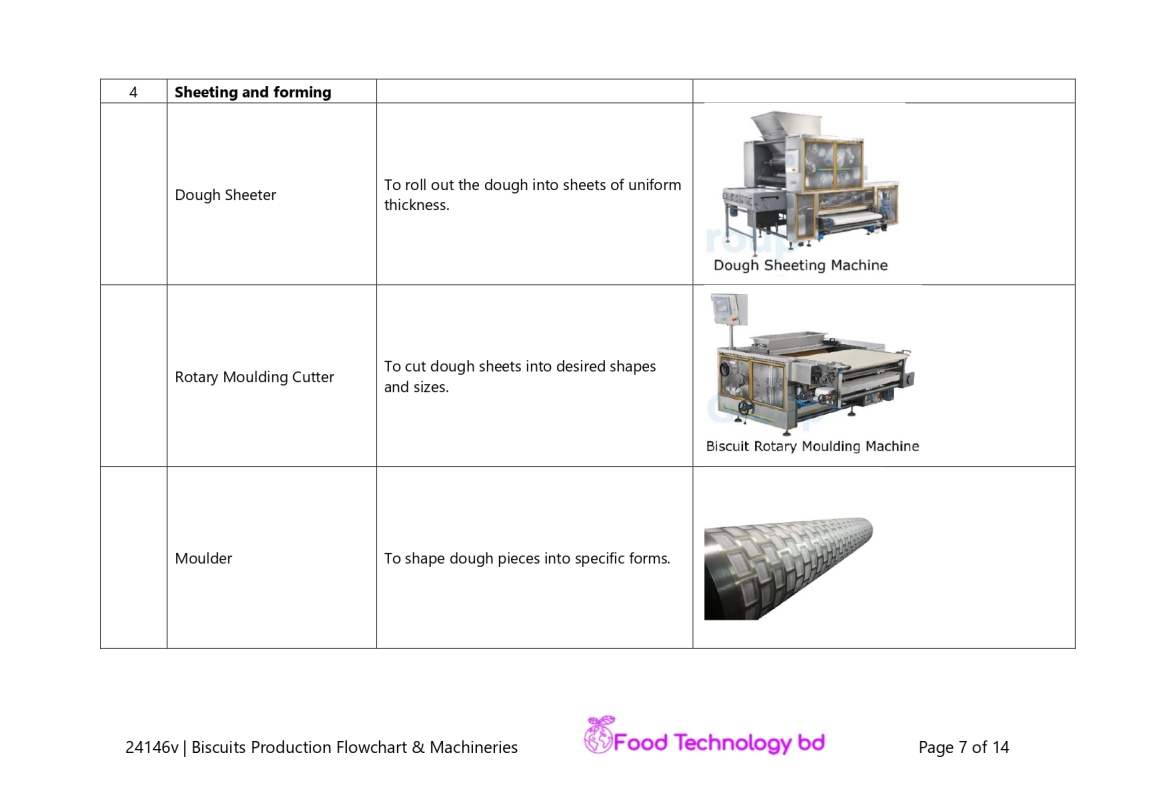

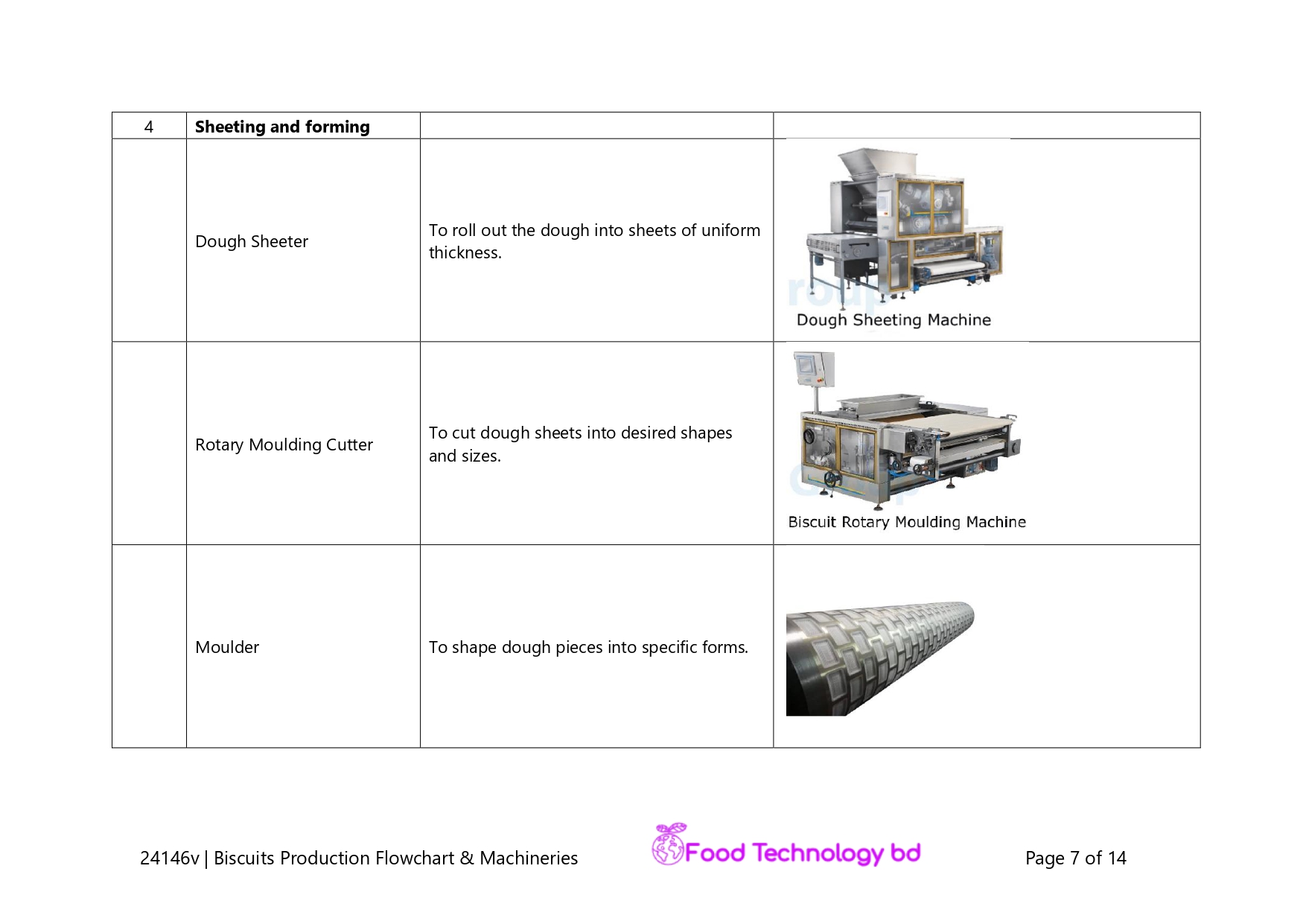

| 4 | Sheeting and forming | |

| Dough Sheeter | To roll out the dough into sheets of uniform thickness. | |

| Rotary Moulding Cutter | To cut dough sheets into desired shapes and sizes. | |

| Moulder | To shape dough pieces into specific forms. | |

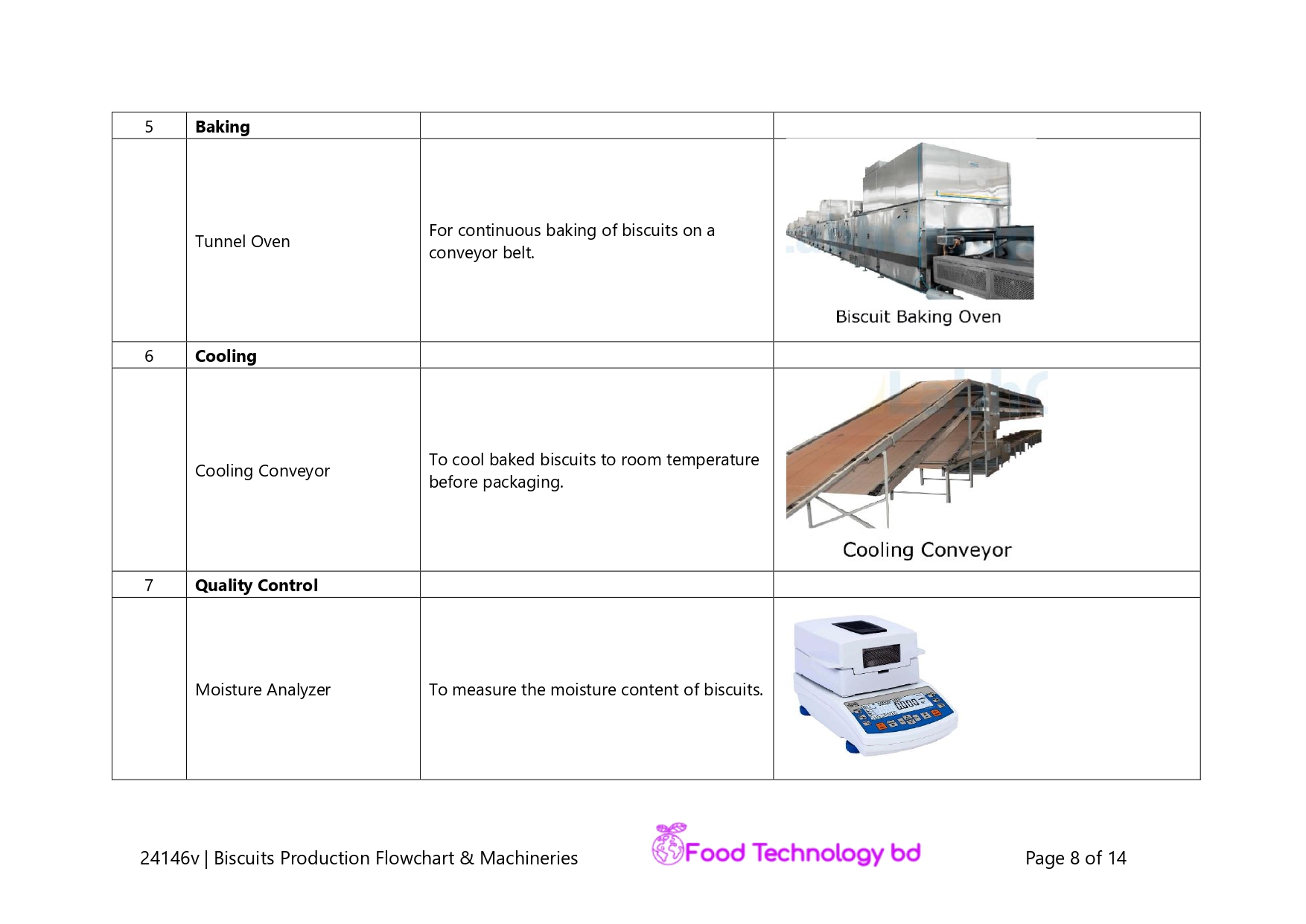

| 5 | Baking | |

| Tunnel Oven | For continuous baking of biscuits on a conveyor belt. | |

| 6 | Cooling | |

| Cooling Conveyor | To cool baked biscuits to room temperature before packaging. | |

| 7 | Quality Control | |

| Moisture Analyzer | To measure the moisture content of biscuits. | |

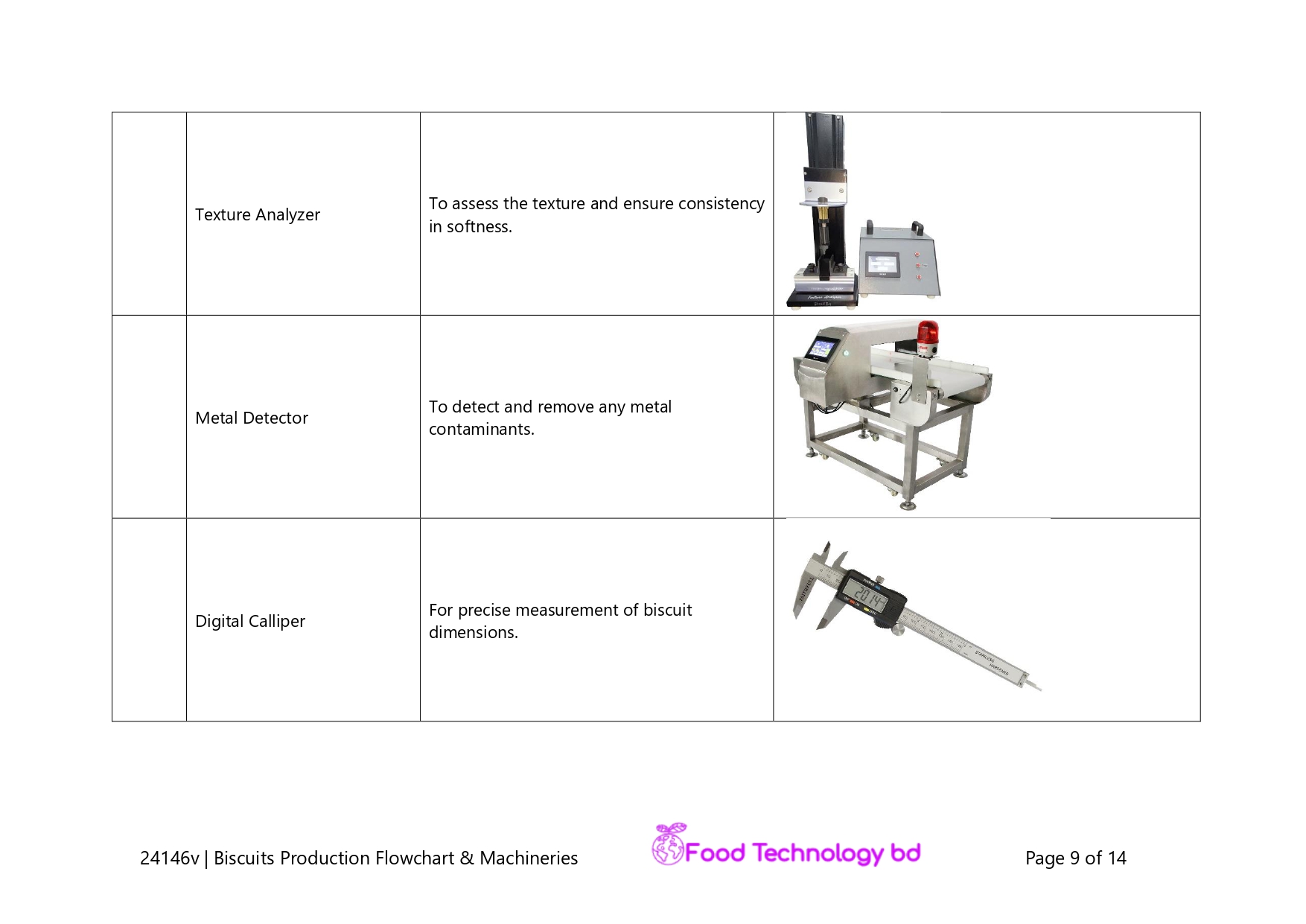

| Texture Analyzer | To assess the texture and ensure consistency in softness. | |

| Metal Detector | To detect and remove any metal contaminants. | |

| Digital Calliper | For precise measurement of biscuit dimensions. | |

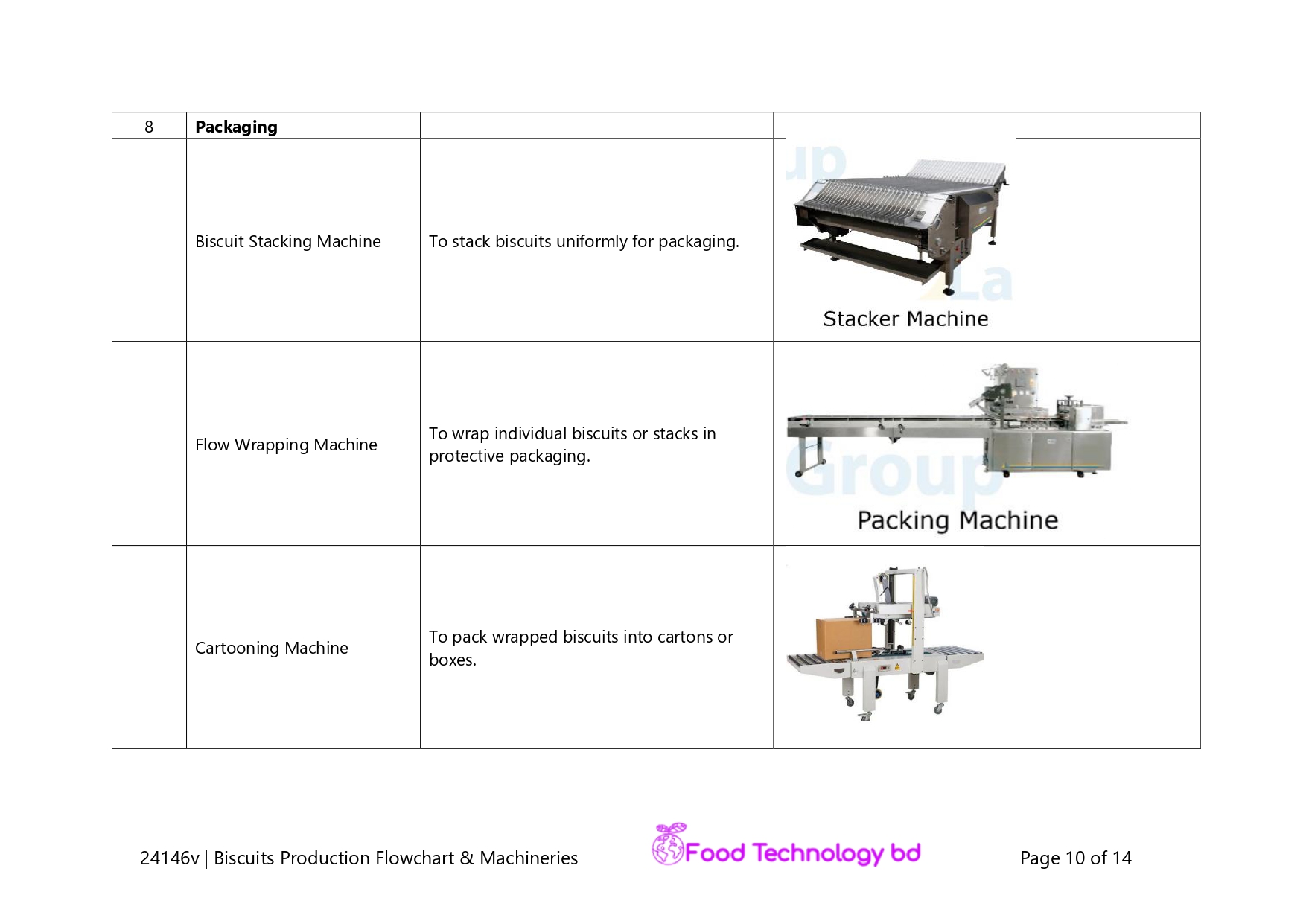

| 8 | Packaging | |

| Biscuit Stacking Machine | To stack biscuits uniformly for packaging. | |

| Flow Wrapping Machine | To wrap individual biscuits or stacks in protective packaging. | |

| Cartooning Machine | To pack wrapped biscuits into cartons or boxes. | |

| 9 | Material Handling and Storage | |

| Trolleys | For transporting ingredients, dough, and finished products within the facility. | |

| Conveyor Belts | To move products between different stages of production. | |

| Forklifts and Pallet Jacks | For moving bulk ingredients and finished goods. | |

| 10 | Cleaning and Maintenance | |

| Pressure Washers | For cleaning floors, walls, and equipment. | |

| Hand Tools (Wrenches, Screwdrivers) | For routine maintenance and repairs. | |

| 11 | Safety and Utilities | |

| Personal Protective Equipment (PPE) | For ensuring worker safety (gloves, goggles, aprons, etc.). | |

| Fire Extinguishers | For handling fire emergencies. | |

| Generators | For backup power supply to prevent production downtime. | |

| Air Compressors | To supply compressed air for pneumatic systems and cleaning purposes. | |

| HVAC System | To regulate temperature and humidity levels within the facility. |